Bubbles, Butanol and Bacteria: A Fascination with Fermentation Inspired Nick Harris ’06 To Found Innovative Businesses

Sunny spring weather invites us all to reconnect with the outdoors. Trees, flowers, and thousands of other lifeforms emerge, and we’re reminded of the interplay of chemistry, biology, physics, geology, and time as new fruits and vegetables come to farmer’s markets and produce stands. As spring moves into summer, the heat rises, and sometimes we find ourselves thirsty for a unique, refreshing beer. Maybe one with pineapple notes. CRMS alumnus Nick Harris ’06 is the person you want to call. His journey from the Roaring Fork Valley, where his parents owned the legendary Woody Creek Tavern, to CRMS and eventually a Ph.D. from one of the best science and engineering programs in the country can be summed up in his passion for a better beer.

Sunny spring weather invites us all to reconnect with the outdoors. Trees, flowers, and thousands of other lifeforms emerge, and we’re reminded of the interplay of chemistry, biology, physics, geology, and time as new fruits and vegetables come to farmer’s markets and produce stands. As spring moves into summer, the heat rises, and sometimes we find ourselves thirsty for a unique, refreshing beer. Maybe one with pineapple notes. CRMS alumnus Nick Harris ’06 is the person you want to call. His journey from the Roaring Fork Valley, where his parents owned the legendary Woody Creek Tavern, to CRMS and eventually a Ph.D. from one of the best science and engineering programs in the country can be summed up in his passion for a better beer.

After completing his senior year at CRMS in 2006, Nick Harris ventured first to Colorado College but it wasn’t quite the right fit. “I transferred to College of the Atlantic in Bar Harbor, Maine, and actually I wish other CRMS students knew more about it. With only 350 students, it’s a very personal education and a great sense of community. And like CRMS, you become great friends with your teachers.”

Nick hadn’t been entirely sure what he’d study there, but comfortable with the sense of openness and mutual respect, he began exploring what the small college had to offer. He was also starting to explore home brewing as a hobby. One day Nick found himself talking to a chemistry professor, and eventually enrolled in one of Professor Don Cass’s classes.

“Don encouraged using brewing as a way to learn about chemistry. It was the kind of ‘real life’ teaching that felt very familiar to what I learned at CRMS—the teaching style was the same. Experiential education is so powerful. I took organic and biochemistry from him, with the goal of becoming a better brewer. I saw beer as a complex mixture of molecules and I thought that I could make the best beer in the world if I understood the biochemical reactions that form each of the molecules. If I could understand the chemical process, then I could reverse-engineer it.”

A fortuitous class on Social Entrepreneurship around the same time presented Nick with the challenge of going out into the community to identify an issue that could be solved with a unique business concept. Science, business, and environmental awareness dovetailed.

“One of my classmates was interested in organic waste and composting, and I was interested in fermentation, so when she talked about all of this carbon that goes to waste, I realized this organic material could be used in a bacterial fermentation process to create a biofuel called butanol,” a combustible fuel source with far more energy density than traditional hydrocarbons like oil and gas. While at CRMS, Nick had been a part of the school’s Bio-Diesel service crew, working with former faculty member Smith Maddrey, classmate Garett Bjorkman ’06 and others to convert used vegetable oil from local restaurants and the Bar Fork kitchen into fuel for a donated diesel farm truck. Despite the time bio-diesel-soaked rags accidentally caught fire in the Bar Fork laundry room, Nick drew from that experience in forming his first company.

“We teamed up with some other students and started a business called Gourmet Butanol. We liked to say that ‘we turn yesterday’s eggplant parmesan into tomorrow’s fuel!’ We won grants from EPA, NASA, and won a couple of business plan competitions, but eventually, it turned into a consulting business.”

After graduating from College of the Atlantic in 2012, Nick parlayed his scientific investigations with Gourmet Butanol into designing a biobutanol facility for Colorado Mountain College in Rifle. His good friend Morgan Williams ’03 had been working with another member of the CRMS family, former trustee George Stranahan, to consult with local ranchers on ways to keep their land profitable and sustainable in the midst of environmental and economic change. Morgan, with whom Nick had been friends since childhood, reached out with an idea.

“Morgan helped convince CMC to hire me to help them build a biobutanol facility, which could help the school diversify training for oilfield workers. I spent more than a year working in collaboration with Colorado State University to put it together. We wanted to use grasses grown on marginal land as a feedstock to make butanol. During this time, I learned a lot about scaling fermentation processes.”

“Morgan helped convince CMC to hire me to help them build a biobutanol facility, which could help the school diversify training for oilfield workers. I spent more than a year working in collaboration with Colorado State University to put it together. We wanted to use grasses grown on marginal land as a feedstock to make butanol. During this time, I learned a lot about scaling fermentation processes.”

Although the facility did not end up producing the quantities of butanol Nick had hoped for, the experience inspired him to continue his journey deeper into the microbial world. Ultimately this experience would lead him to pursue a Ph.D. in Microbiology at the University of California, Berkeley.

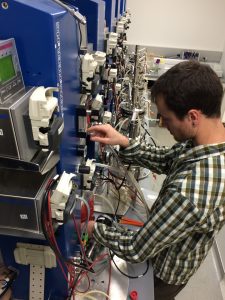

“I was familiar with fermenters, but I didn’t fully understand how the bacteria functioned in the butanol process. I applied only to schools with applied microbiology in the energy realm and ended up choosing Berkeley because they had an entire department focused on biofuels. I joined Prof. Wenjun Zhang’s lab. Her lab specialized in natural product discovery, which means that we would identify novel chemicals (mostly made by bacteria) with complex analytical techniques like mass spectrometry and nuclear magnetic resonance. We would decipher how multiple enzymes worked in concert to produce these novel chemicals, and in the process, we would often discover new ways that biochemical reactions can occur. It might sound complex but on the day-to-day, it’s a lot of moving very small volumes of liquid from one tube to another. My first project was done in collaboration with the energy company BP. I worked with a postdoc to discover a new method for making undecene, which is a replacement for diesel fuel. However, shortly after we published our results, the company pulled our research funding. I was fortunate enough to have landed a National Science Foundation Graduate Research Fellowship, which covered the rest of my tenure at Berkeley, but my research shifted away from biofuels and onto human health. I began studying Mycobacterium tuberculosis, which is the causative agent of tuberculosis. This bacterium has a set of genes that affect the severity of the disease, but the function of these genes was previously unknown. I was able to figure out what these five genes do during the course of an infection. That research led to a couple of scientific papers including one published in the Proceedings of the National Academy of Sciences.”

Despite his graduate research spanning applications from energy to human health, Nick remained focused on his passion for brewing a better beer. Near the end of graduate school, Nick met two other researchers at UC Berkeley who developed a prototype yeast strain that made terpenes, a class of chemicals that make hops smell hoppy. Realizing the potential for this innovation, Nick teamed up with these researchers and together, they formed Berkeley Brewing Science in a small garage.

Four years later, the company, now known as Berkeley Yeast, genetically engineers specialty yeast strains for numerous craft and microbreweries from a large warehouse in West Oakland. Nick and his company use the same techniques that many universities use, resulting in yeasts that can produce a hoppier or fruitier beer—like one with pineapple flavors—without having to use as much of those other ingredients in the brewing process. Hops, for example, have a heavy environmental footprint in terms of their water use and the energy needed to process and transport them. By reducing the need for more hops, Nick’s work helps reduce the impact of brewing on the environment while also enabling craft brewers to take their creations in new directions.

Public discourse about genetically modified foods understandably raises questions for many, and Nick enjoys bringing the science forward in a way that’s clear and welcoming.

Public discourse about genetically modified foods understandably raises questions for many, and Nick enjoys bringing the science forward in a way that’s clear and welcoming.

“We don’t use CRISPR, but we use other open-source gene-editing technologies,” he says, noting that their yeast strains are FDA approved and that they result in only food-safe molecules and flavor compounds that already exist in nature. It’s not “super-yeast,” he says.

“I think that the biggest hurdle was that brewers were scared of what their consumers would think, but we’ve found that once they use it and advertise that they use it, they’re fine with it. I mean, we’re not Monsanto. We’re just making yeast that’s more expressive or helps make a beer taste better without off-flavors or have a unique taste to it. We work closely with more than 100 breweries across the US, and we’ve made more than 1,000 yeast strains.”

In fact, Nick feels the technology has a number of interesting applications. “Any process that uses yeast or microbes—there are definitely other avenues that can use this technology. Beer is a great way to have a proof of concept, but there are a ton of other avenues. Bread, wine, kombucha, and health beverages with healthy compounds.”

Reflecting on his time at CRMS and what he took from it over the past fifteen years since graduation, Nick encourages graduating seniors “to seek out connections in everything that you learn. How does what you are learning relate to the rest of your life? How does it relate to nature and the environment? Why does it matter? I find that when you seek to establish these connections that it cultivates a sense of purpose and it also stimulates curiosity.”

MYCRMS

MYCRMS

Virtual Tour

Virtual Tour